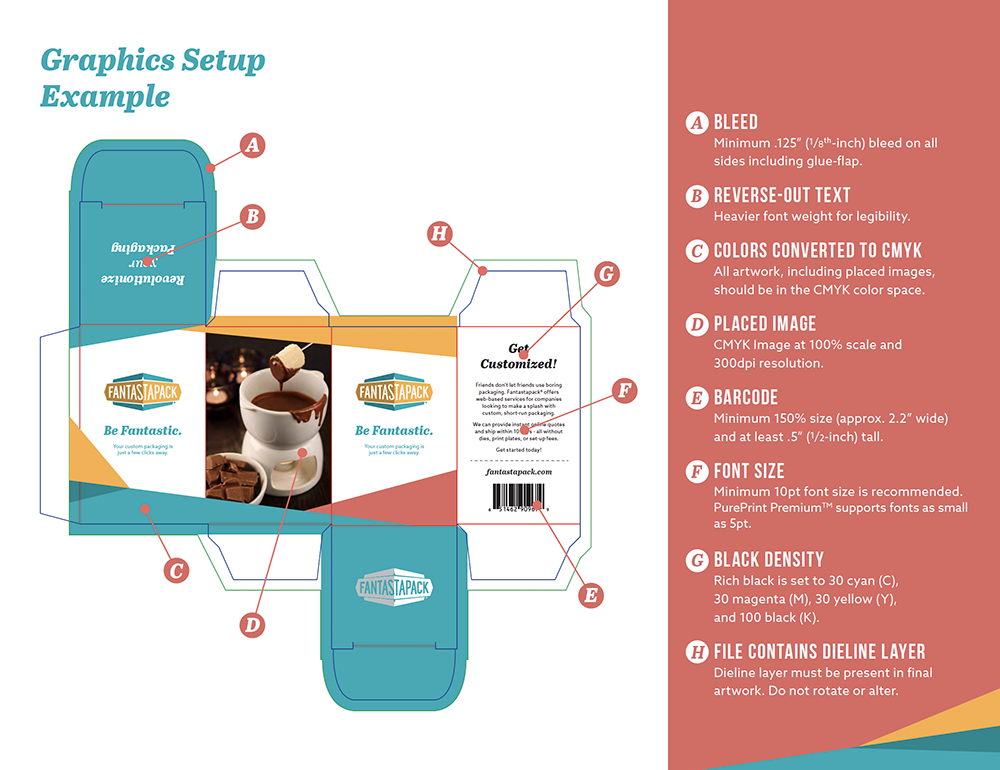

Follow these simple rules to get the best print results for your custom packaging.

Do Not Rotate Structural Drawing

The unique structural template (CAD dieline) we send you to build your art has been designed to flow through our system smoothly and accurately. It is very important that this template not be altered or rotated. The printed art is cut out based on the original template orientation. Rotating the dieline in your artwork may yield unintended results.

File Contains Dieline Layer

In order to ensure your custom packaging cuts correctly, it is very important that the unique structural dieline we send you is included as part of the print file. The structural drawing will contain Spot Colors for the cut and crease lines in the Swatch menu. These colors are used to tell the cutting and creasing machines how to convert your unique product.

Please note: Do not change these to CMYK colors because they will print on your box or label.

Add Your Custom Artwork to a New Layer

Within Adobe® Illustrator, create a new layer below your dieline layer to add your custom artwork. All artwork added to this layer should be CMYK (no Pantone or spot colors).

Black Ink Saturation

Too much ink in any one area can lead to printing and drying issues, which affect everything from how quickly your project can be printed to possible issues in the cutting and finishing processes. Too much ink saturation can lead to other problems like ink smearing and smudging.

For instance, black elements built using 100% Black, 100% Cyan, 100% Magenta, and 100% Yellow have ink coverage of 400% which will not cure properly and result in quality and production issues. Using a color build of 100% Black, 30% Cyan, 30% Magenta, and 30% Yellow, you end up with a similar result without the print issues.

Rich Black

If your art includes black, we recommend it's built as a rich black with 30 Cyan (C), 30 Magenta (M), 30 Yellow(Y), and 100 Black (K). For best results, include a .5pt stroke of 100% black (K) to avoid print overspray.

Color Settings

All artwork should be converted to CMYK. Please convert any RGB colors and images to avoid unexpected color shifting. All Pantone (PMS) colors should be converted to CMYK. Pantone and spot colors are not supported.

We do not provide services such as color matching or color proofs. The best way to get the desired result is to convert your Pantone to CMYK and buy a sample of your box first before committing to a larger order.

File Format

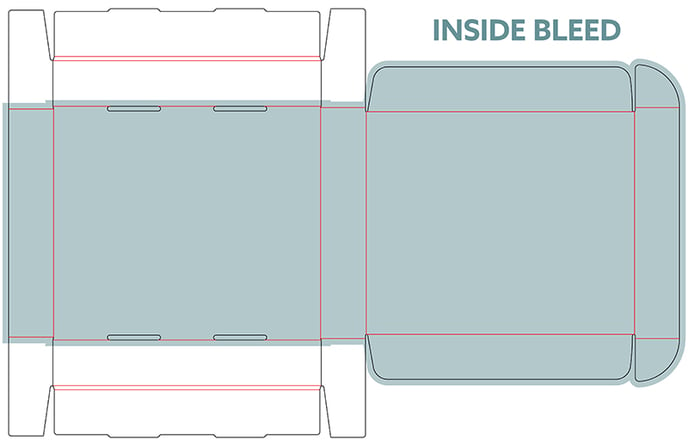

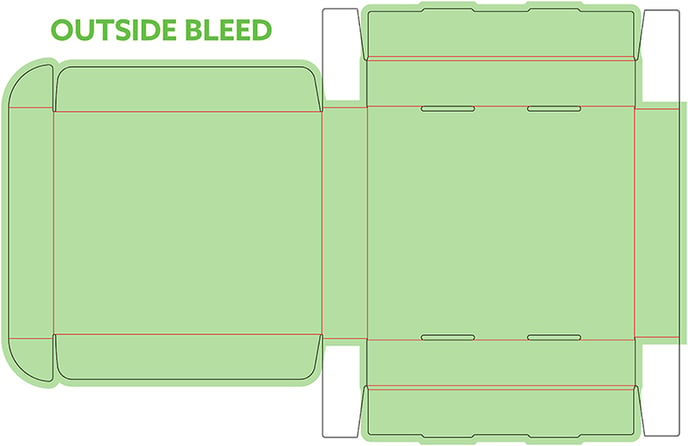

Fantastapack accepts only PDF files. It is best to use a vector-based software application such as Adobe Illustrator for building art files and saving/exporting your native file in PDF format before uploading it to Fantastapack. Two-Sided Print projects must be saved as a single PDF file where page 1 is the outside print and page 2 is the inside print. Your file must be in this order for our automated system to function.

Fonts & Type

For Standard White and Premium White boxes, we recommend using font sizes of 10 or larger. For PurePrint Premium™ or PurePrint Matte™ and custom label orders, we recommend using font sizes of 5 or larger. Fonts below the recommended sizes may not print legibly, especially if the font is thin or contains thin features such as serifs or crossbars.

![]()

Line Weight

When reversing type, use one weight heavier than the weight you intended to use. Lines and stroke weight should be no less than .5pt and 1pt if reversed out. Avoid specifying small trademarks and register mark symbols to print in reverse, as they may fill in when printed.

Convert All Text to Outlines

In order to ensure your custom packaging prints correctly, we require that all fonts be converted to outlines.

Bleed

Final artwork files must maintain a minimum bleed of .25" (1/4-inch) on all edges and into the glue flap. If the dieline provided does not contain a bleed line, please contact customer support at support@fantastapack.com.

Safe Area

Margins, rule outlines, or copy that does not bleed needs to be no less than .125" (1/8th-inch) away from dieline and scores.

UPC/Barcodes

UPC-A type barcodes need to be at least 150% size (approx. 2.2” wide). In order to scan properly, the height of the bars is not as much of a concern, but we recommend them to be at least .5” (1⁄2-inch) tall.

![]()

Image Resolution

Check image resolution in order to provide the best quality print. If images are at a resolution of 150 dpi or lower at a 100% scale, this can result in a loss of sharpness and a "pixelated" look. Straight lines will have a "staircase" effect.

For best results, all artwork and image resolution should be no less than 300 dpi.

Placed Images

All images should be embedded in your artwork file PDF. Make sure placed images have the correct file extensions: ".tiff" or ".eps" at the end (e.g., "Image.tiff" or "Image.eps"). Include only the page layout documents and the supporting files required for your project. Place graphics at 100%. Any graphics placed less than 100% take longer to output and may require additional prepress time. Placed images and artwork should be in the CMYK color space.